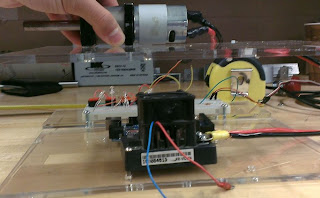

We look to fine tune the motor box model tonight in order to have the electrical components in their proposed places in time for the technical review.

In addition, we took a hacksaw again the the steel sheet and finished the freeing process of the rings, producing three individual ones: